Abrasion-resistant steel is a vital material in industries that face heavy wear and tear, such as mining, construction and quarrying. Its remarkable durability against mechanical wear significantly extends the lifespan of machinery components, reduces the need for frequent replacements and minimises costly operational downtime, ultimately improving efficiency and productivity.

Developed by Industeel, Creusabro 4800 and Creusabro 8000 are among the most advanced materials in this category, setting a high standard in wear-resistant steel technology.

At Brown McFarlane, we have been awarded UK and Ireland exclusivity for the distribution of Creusabro® 4800, Creusabro® 8000 & Creusabro® DUAL products, giving us first hand insight into the applications and exceptional performance levels of this unique material.

Using this experience, we’ve put together an in-depth analysis of the distinctive properties of Creusabro abrasion-resistant plates, outlining the industries where these materials are most effective, examining how their integration can help businesses optimise operations and enhance productivity.

What is Creusabro Abrasion Resistant Steel?

Creusabro is a family of high-performance wear-resistant steels engineered for aggressive environments. Unlike traditional low-alloyed abrasion-resistant steel, Creusabro plates are enriched with advanced alloying elements such as chromium, nickel, molybdenum and titanium. These compositions, combined with specialised heat treatments, ensure properties that outperform conventional AR steel grades.

Renowned not only for their exceptional resistance to wear but also for their outstanding workability, Creusabro plates are easier to process and integrate into complex industrial applications. This combination of performance and practicality has made Creusabro a trusted choice for industries requiring reliable and long-lasting solutions in harsh operating conditions.

Key Creusabro Grades

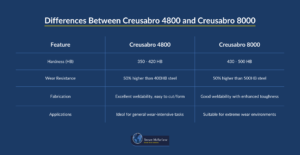

Creusabro 4800

- Wear resistance is up to 50% higher than conventional 400HB water-quenched steel.

- Remarkable performance in abrasive, impact-heavy environments.

- Operates efficiently in temperatures ranging from 350°C to 450°C.

- Maintains exceptional workability for fabrication purposes.

Creusabro 8000

- Provides wear resistance 50% better than 500HB steel.

- Engineered for the most challenging industrial settings with superior longevity.

- Combines high hardness with excellent weldability and structural toughness.

Explore our Creusabro products.

Industries and Applications for Creusabro Plates

Creusabro plates are essential in industries that demand resilience and durability in abrasive conditions. This includes:

- Mining and Quarrying

- Equipment like crushers, conveyors, excavators and chutes bear the brunt of continual material abrasion.

- Applications include digger buckets, wear liners and screens subjected to heavy impact and frictions.

Creusabro plates are engineered to thrive in high-abrasion environments, significantly reducing maintenance frequency and costs in mining and quarrying operations. For example, Creusabro 8000 offers unmatched durability in crusher components, extending their service life by up to 50%

- Construction and Demolition

- Creusabro plates are used in graders and demolition equipment which are constantly exposed to heavy-duty tasks, such as moving earth, leveling surfaces and breaking through tough materials.

Construction companies value Creusabro 4800 for its balance of strength and ductility, ensuring minimal wear and tear while maintaining productivity. Its superior resistance handles the grit and debris commonly encountered in these operations.

- Agriculture

- Agricultural machinery, such as ploughs, harvester blades and tilling equipment, endure significant wear and tear due to constant exposure to abrasive elements like soil, rocks and rubble. This repeated friction and impact can reduce the efficiency and lifespan of the equipment.

Creusabro’s superior toughness minimises replacements for parts exposed to such abrasive environments. By utilising Creusabro plates for their equipment, agricultural businesses experience less downtime and greater operational efficiency.

- Energy and Recycling

- Waste processing plants and renewable energy systems rely on the durability and performance of Creusabro in critical components such as shredders, hoppers and boilers. Its exceptional wear resistance and toughness make it ideal for handling abrasive materials and high-impact environments, ensuring long-lasting efficiency and reduced maintenance.

Energy industry applications benefit from Creusabro’s ability to withstand not only material abrasion but also high operational temperatures. Whether shredding scrap materials or operating in renewable energy facilities, Creusabro 8000 ensures longer lifespans for machinery.

Choosing the Right Creusabro Grade

Choosing the right Creusabro grade requires a thorough evaluation of your specific application needs to ensure optimal performance and durability.

First, it’s important to assess the working environment in which the material will be used. Consider factors such as levels of abrasion, exposure to high or low temperatures and the presence of humidity or moisture that could impact its performance.

Additionally, you need to determine the ideal balance between hardness, toughness and ease of fabrication to suit your operational requirements. Each Creusabro grade offers unique properties, and selecting the right one can significantly enhance the efficiency and longevity of your equipment.

At Brown McFarlane, our team of experienced professionals is available to guide you through the selection process, helping you find the perfect grade to meet the challenges of your operational environment.

Contact our team today to discuss your requirements and gain access to one of the largest selections of high quality steel plate products in the world, alongside a comprehensive suite of expert steel processing services, all designed to elevate your operations.

Related News

Steel Plate Processing for Custom Industrial Components

The Importance of Steel Profiling & Weld Preparation